FOWLER WESTRUP (INDIA) P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FOWLER WESTRUP (INDIA) P.LTD.

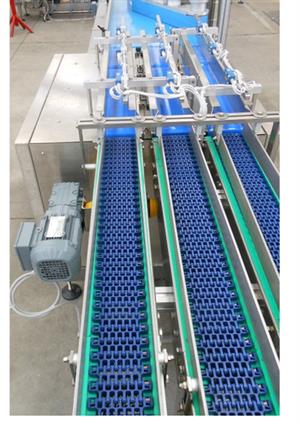

Sooji Sorter

The AUTOSORT MC Range uses a rapid sequence of different coloured lights to obtain ‘more than colour information’ from the product. Often, even very similar colours can be differentiated. The infra-red capability improves detection of foreign bodies. The camera information is processed by an ultra-fast digital signal processor, and commands are sent to one or more ejectors to remove the unwanted item efficiently.

The MC-A is specifically configured for efficient sorting of difficult to handle, lightweight products such as green herbs or flakes. After being spread on a vibratory feeder, the product accelerates down a chute and is inspected by the 2048 pixel line-scan camera. Defects and contaminants are removed by short puffs of air from ejectors built into the feed system. The unique shape of the chute and configuration of ejectors ensure very high efficiency of defect removal and low wastage of good product.

Application:

Dehydrated Herbs, Chives, Coarse Powders, Semolina (Sooji)

Potato Flakes, Dry & Frozen Foods, Breakfast Cereals, Soya Granules, Chilli Flakes,

Dehydrated Onions, Psyllium Husk, Sugar & Other Light Weight Products

Benefits :

Natural materials contain impurities and less-than-perfect product. By removing discolouration and contamination, the quality and value of the finished product is increased, or lower grade raw material can be used. The customer will be rewarded with consistent quality product. Also food safety is enhanced by ensuring that foreign bodies and contamination are removed before it reaches the consumer. Added value all round.

Features :

- Optical lighting in four bands from visible to infra red

- Rapid LED lighting

- Inspection in 2, 3 or 4 specific parts of the spectrum

- High resolution cameras from 0.3 mm

- Flexibility – Optional mono-chromatic Fluorescent lighting to suit product

- 2 sizes: 672mm, 1344mm

- Compact Footprint

- Independent vibrator

- Food grade Stainless Steel construction

- 64 or 128 fast ejectors. Can be configured to 128 or 256 ejectors for precise ejection

- Minimum good product removal

- Easy setup with large touch screen

- Facility to store and recall several programme modes for multiple products

- Auto-calibration and self cleaning

- Remote maintenance through modem connection

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.